of uninterrupted production

Saratovdizelapparat traces its history to the creation of the Saratov inter-farm workshop of the People's Commissariat of State Farms of the USSR in 1933. For all the years of operation, the plant has never stopped production

Machine Tools

In 2014, a course was taken on the technical re-equipment of the plant and the use of CNC machines and multi-purpose processing centers

products produced in the entire history of the plant

In 1969, the first prototype speed regulator was released. After 3 years, the plant became the only specialized enterprise for the production of speed regulators for all diesel construction plants in the country

of metal machining

The largest share in production is the machining of parts made of steel, cast iron, aluminum alloys, brass and plastic - complex configuration and high accuracy

Modern production

A powerful production base allows you to implement a full cycle of manufacturing, processing and assembly of products at the enterprise.

The fleet of equipment includes universal turning, milling machines and turning-and-revolving machines, a variety of drilling and toothworking machines, and grinding group machines.

The manufactured parts and assemblies are manually assembled using special equipment and mechanized tools in separate assembly areas and tested on specialized stands.

Supporting infrastructure

The plant is equipped with its own laboratory for diagnostics and analysis of galvanic coatings, wear resistance of rubber components and metallographic studies.

Compliance with the temperature regime in the workshops can reduce the impact of the medium on the metals being processed.

15

test benches

18

cranes with a lifting capacity of 5 tons

nitriding chamber

heat treatment area

paint shop

Quality control

All manufactured products undergo three-stage control:

- incoming quality control of the raw material base

- interoperational control

- final control

The assembly shop of the plant is equipped with specialized bench equipment (mechanical, hydraulic, pneumatic), which allows to perform reliable measurements of the parameters of the manufactured products and life tests.

The own metrological service regularly performs maintenance, calibration and repair of control tools and tools and ensures the unity of the required measurement accuracy.

Patents and Certificates

Saratovdizelapparat has implemented the 5S system (lean production) and uses a quality management system in accordance with the GOST ISO 9001-2015 certificate.

The company is accredited by the military representative 634 VP of the Ministry of Defense of the Russian Federation and has certificates of recognition of the manufacturer - the Russian Sea and River Registers.

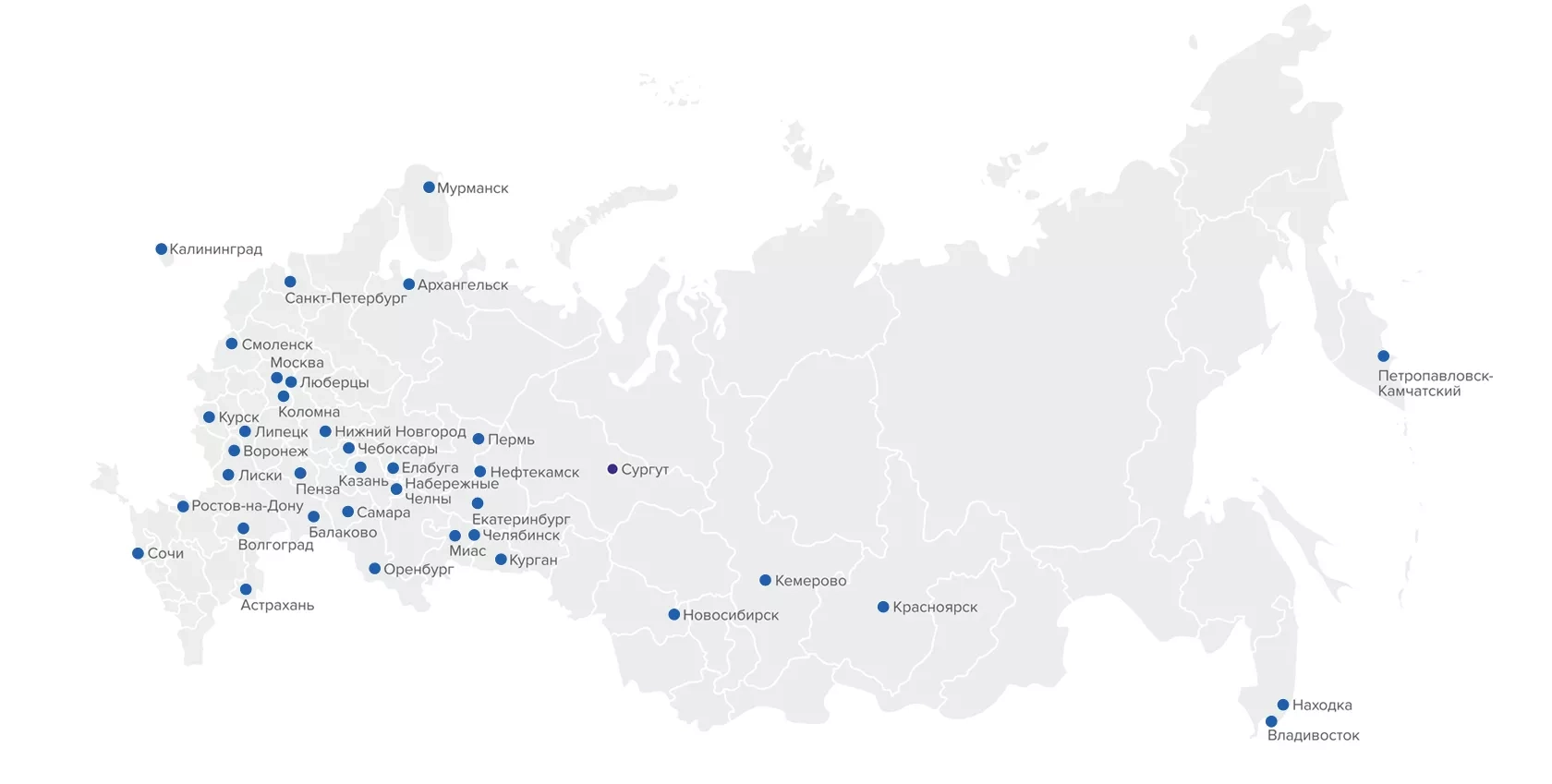

Supply chart

Regions of Russia to which the products of the Saratovdizelapparat plant are supplied

Our partners